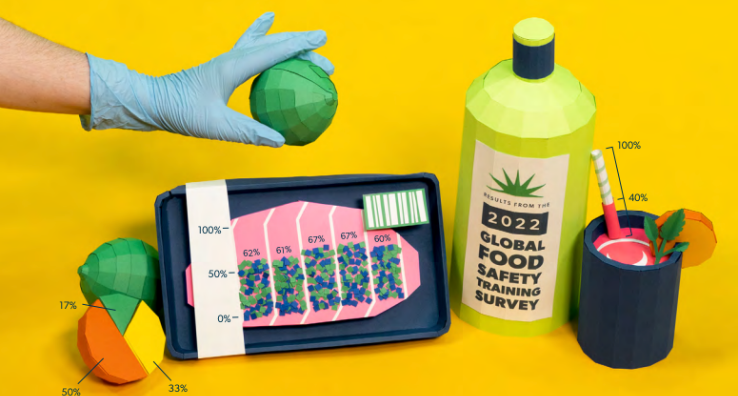

Intertek Alchemy’s 7th Global Food Safety Training Survey Reveals the Good and Bad of Training Practices Around the World

This week, we’re releasing new research based on analysis of the 7th Global Food Safety Training Survey. The results represent the most comprehensive research and assessment of food safety training practices, with data from more than 3,000 food production facilities around the world.

The survey is sponsored by Intertek Alchemy and Campden BRI, in partnership with BRCGS, BSI, Cultivate, SGS, Safe Quality Food Institute, and TSI.

Analysis of the survey data reveals specific actions and characteristics that enable companies to have stronger food safety outcomes. The research uncovered what companies with stronger food safety programs are doing right when it comes to training.

The study also shows what companies with poorer results are doing wrong, or not at all. The findings are presented in detail in the new report: Why Some Programs Succeed Where Others Fail: Results & Analysis from the Global Food Safety Training Survey.

The research also sheds light on numerous challenges and contradictions of current food safety training practices. For example, 88% of companies said they believe they provide adequate levels of food safety training to drive consistent and appropriate food safety behaviors. Yet only 40% of their employees follow food safety programs on the manufacturing floor.

The report highlights shared industry challenges and measures that can be used to overcome them. Some of the key findings from the survey include:

- 81% of companies understand what it takes to build and sustain a strong food safety culture. But only 22% strongly agree that their employees have the authority to take action when food safety is compromised.

- 80% of companies believe they would be more productive if their employees consistently adhered to their training programs. However, only 19% of companies are increasing their budget for food safety training, and only 18% plan to add new training technology next year.

- Tailoring training to specific job roles increases the likelihood from 22% to 82% that a frontline employee will halt production when necessary to prevent a food safety incident.

- Highly motivated employees are over two times more likely to consistently adhere to food safety protocols on the floor.

- 78% of companies with a mature upskilling program have highly motivated employees, compared to 43% for companies without an upskilling program.

Overall, we think this report, “Results & Analysis from the Global Food Safter Training Survey,” presents some of the most eye-catching findings that will help food manufacturers improve food safety training outcomes.

For a closer look into our findings, check out a complimentary copy of the research paper at www.alchemysystems.com/content/research/food-safety-training-survey/

Leave your feedback and questions below or contact us for a discussion on how these findings relate to your food safety training programs.