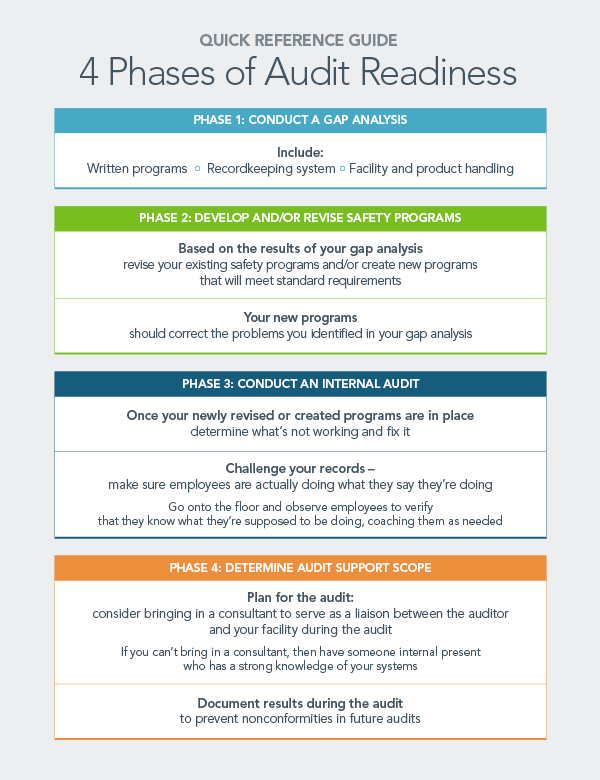

4 Phases of Audit Readiness

We all know the old saying, “Failing to plan is planning to fail.” But in the fast-paced and high-pressure food industry, it can be difficult to find all the time you need to prepare for an audit. Resources are often tight and facilities have to focus on keeping up with daily output to protect their bottom line. However, in the current era of FSMA, GFSI, and increased liability exposure, it’s more important than ever to be prepared for the auditor’s knock.

Phase 1

Start by conducting a gap analysis to identify weaknesses in your food safety system. For example, do you suffer from a lack of in-place procedures or a lack of human resources? Make sure you understand your certification requirements, and keep in mind that your safety programs must not only be written but also implemented.

Phase 2

Next, revise your existing safety programs or create new programs to correct the deficiencies you identified in phase 1. Prioritize your action items based on risk (immediate food safety concerns should receive top priority). As part of your action plan, organize documentation for ease of use. For example, number procedures to correlate with the requirement of the standard.

Phase 3

Now that your safety programs have been revised or created, go back and take the pulse of your system. Conduct an internal audit of your system against the requirements that you wrote in Phase 2 and fix what’s not working. Challenge your records – go out on the floor, make observations, and coach employees to ensure they’re doing what they are supposed to be doing.

Phase 4

Finally, plan to bring in a consultant to serve as a liaison between the auditor and your facility during the audit. If you can’t bring in a consultant, have someone internal present who can challenge the auditor if necessary. This person should have thorough knowledge of your systems. During the audit, document results. Note observations that could be nonconformities and document the corrective actions necessary to prevent them from becoming nonconformities in future audits.

Don’t let audits catch you off guard in 2017. Take a proactive approach by taking the first steps on the journey to audit readiness.

{{cta(‘fb13e38d-7c79-4d57-892e-7562ea19818f’)}}