Microlearning on the Production Floor

Microlearning is the buzzword in the training world. But be warned—it’s not solely a method to learn “faster” or simply have shorter courses.

So let’s first define microlearning to provide clarity, and then explore its benefits.

What Is microlearning?

Microlearning is organizing information into a series of small, digestible chunks that fulfill a specific, clearly defined need. Activities in microlearning environments are typically short but can vary in length due to the complexity of the topic. Basically, it’s about organizing information into concise elements that can be taken independently.

To drive the point home, it is entirely possible for training that utilizes microlearning structure and training that does not to be the same total duration. The difference is the latter is a firehose of information all at once. The microlearning version will be several mini-lessons stitched together, with knowledge checks at each step to ensure comprehension before increasing the complexity.

What are some benefits of microlearning?

The primary benefit is microlearning is more effective.

Breaking it down further, in a typical training environment, it can be hard to determine specifically where individuals are struggling. When content is broken down into smaller components, it is easier to identify the specific topics on which a learner is struggling. This allows training facilitators to pinpoint the trouble spot and overcome it with focused coaching and reinforcement.

And from a development perspective, breaking content into smaller elements makes it more manageable for translating into other languages, or for applying ideas to varying cultures.

So why is microlearning becoming such a buzzword/learning trend?

We are constantly bombarded by information from all directions. Take, for example, the way visual media cuts to different scenes every few seconds. Microlearning allows a learner to focus on a specific concept in a bite size piece. A person can focus on a topic “just in time” when it is needed.

Furthermore, microlearning allows someone to learn about a topic at his or her own pace and review specific elements as often as necessary or preferred, as opposed to having to complete a longer training course each time.

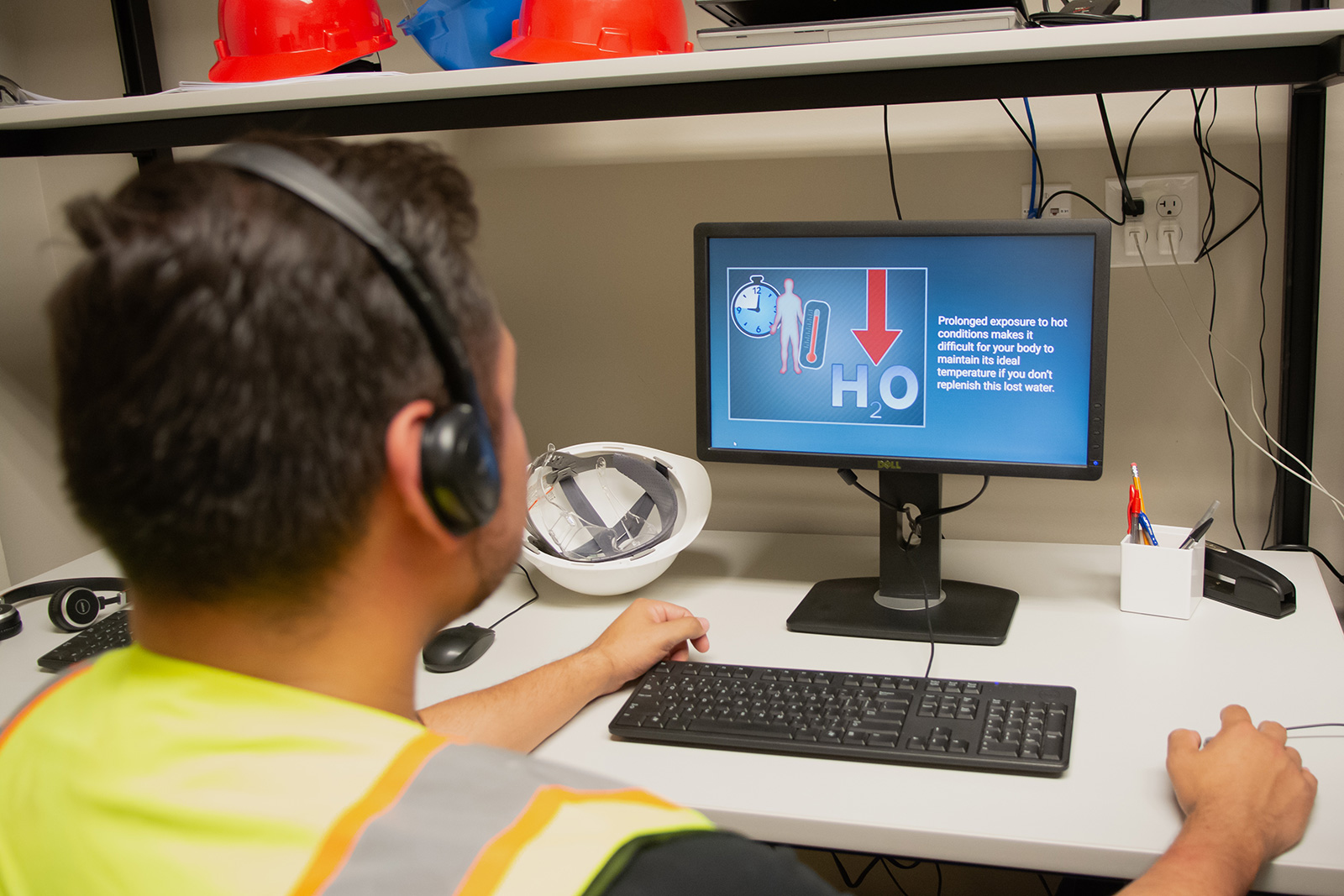

Businesses have warmed up to the concept of microlearning, as it does not require lengthy interruptions of normal work activities. Learners can access short segments of instruction before work, during breaks, or between tasks.

How does microlearning work on the production floor?

Since microlearning is information split into small elements that can stand alone, a safety topic such as Lockout/Tagout (LOTO), can be divvied up into a series of topics such as:

- the purpose of Lockout/Tagout

- the two core components of LOTO (a lock and a tag, and common examples)

- the purpose of a LOTO procedure (types of information included)

- when Lockout/Tagout procedures must be implemented

- the definition of qualified, affected, and other persons in regards to LOTO

- who can implement a Lockout/Tagout procedure

- types of energy a LOTO procedure can control

What about complex topics?

Take what we did with Lockout/Tagout: we broke down the information into a series of small topics, and then indicated the order in which specific topics should be viewed, so that ideas are built in a logical sequence. By following a specified sequence, the learner is exposed to an otherwise complex topic as simple ideas that build upon each other.

For cases in which additional context is needed to explain the intent of a topic, the context can be separated into its own bite size piece.

In Case You Missed It…

The information in this microlearning overview was organized into a series of short topics. Each topic can be presented independently, and together they provide a more comprehensive overview of what microlearning is all about!