Lean Isn’t Mean!

I’ve recently had some interesting conversations with colleagues and clients about lean manufacturing. One theme that continues to come up is the idea that some people see the process of streamlining companies as inevitably leading to layoffs.

While streamlining manufacturing processes is a crucial outcome of lean, workforce reduction is rarely (and I would argue should never be) a result. For example, lean pioneer Toyota has a strict no-layoff policy and has not laid anyone off since the 1950s. Below are four of the more likely outcomes of lean.

- New employee opportunities – Lean can lead to tremendous opportunities for workers to move and advance in different positions. With improved productivity resulting from lean, companies often identify value-added tasks needing more resources and reallocate employees accordingly. Through cross-training and lean manufacturing skills training, teams can perform valuable roles in various departments where there are opportunities for continued growth and development.

- Increased demand – Any workforce excess caused by lean efficiencies is usually temporary. Companies that successfully implement lean processes typically see an increase in demand through improved quality, reduced lead time, and better service. This leads to opening more facilities, managing additional customers, creating new products, and hiring more employees.

- Natural attrition – Manufacturing facilities experience regular attrition, which can adjust workforce levels to meet new efficiencies. I’ve worked with colleagues involved in projects for sizable facilities that did not lose one person in the name of a lean manufacturing change.

- Investing cost savings – Cost savings resulting from the adoption of lean principles are often invested in employees through training, improved benefits, internal celebrations, facility improvements, or other programs that can provide substantial worker and business value. Reinvesting lean savings into employee training offers many benefits, including employee productivity, satisfaction, upper mobility, and retention.

The bottom line is that lean manufacturing empowers workers and engages them to help companies operate more efficiently when implemented correctly. When employees fully understand lean manufacturing and its benefits, they are empowered to contribute to a collaborative effort to improve productivity that helps companies grow and thrive. Successful companies value and keep their employees for the long haul.

Petra Sterwerf, Director of Operations at Skyline Chili, an Intertek Alchemy client, joined me for a recent webinar to discuss the benefits of Lean process improvement, implementation steps, pitfalls to overcome, communication techniques, and of course, training best practices. You can watch the webinar here: The Art of Lean: Recognizing Waste & What to Do About It.

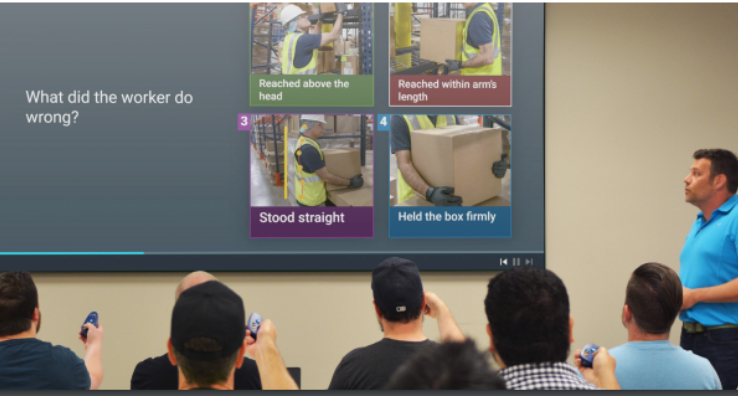

To bring structure to the Lean training strategy, we recently rolled out the Alchemy Lean Manufacturing Training Library, which consists of 10 e-Learning courses that help managers and supervisors identify and eliminate inefficiencies and production waste in their organizations.

Each course ends with knowledge check questions and a call to action to encourage participants to practice what they learn on the shop floor. I’m proud to say that Petra added her expertise, which greatly informed the course content.

Feel free to contact us if you’d like to learn more about how the Alchemy Lean Manufacturing Training Library can jumpstart your lean journey.