Setting Passing Rates for Food Industry Training Courses

By design, training courses should be created to focus on critical learning objectives that are foundational across the broad food industry to reduce a plant’s risks. Typically, many of these courses are needed for compliance to GFSI schemes such as SQF, BRC, IFS, FSSC 22,000; regulatory requirements including those from USDA-FSIS, FDA, and OSHA; and EPA and NLRB requirements. Specific courses can be created to achieve a variety of goals, such as compliance to internal standards, proficiency in job tasks, increased productivity, general awareness and communication, culture-building, etc., so score achievements in these areas are obviously discretionary.

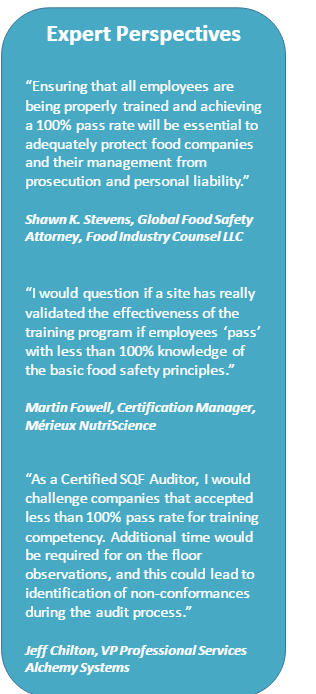

Audits and Total Comprehension

Setting a passing score is not something to be taken lightly. Plants will need to have an effective, defensible way to address questions from auditors, customers, FDA investigators, USDA-FSIS, or OSHA inspectors when setting a passing threshold of less than 100% competency or comprehension on the critical questions from their training. Justification why a lack of total comprehension doesn’t introduce risk into their operations should be documented and science-based.

For FDA plants subject to FSMA rules, the documentation of qualified individuals’ will potentially receive even greater scrutiny with the compliance date for large facilities set for September 2016 and 2017 for medium-sized facilities. FDA knows plants are training on the ‘must haves,’ so those training records must be defensible.

Testing within a course or attached to a course is not the only way to demonstrate competency.

For example:

Some plants may elect to use the Coach app to close knowledge gaps through one-on-one interaction and documentation that the knowledge has been attained and demonstrated.

Some plants may elect to use the Coach app to close knowledge gaps through one-on-one interaction and documentation that the knowledge has been attained and demonstrated.

A passing rate set at 100% will rarely – if ever – raise questions from inspectors, investigators, or auditors. Anything less will draw additional attention, and exceptions like this must be supported with a written justification based on sound science.

Ask yourself the following questions before you set a passing rate that is less than 100%:

- Have I really thought it through and considered what justification would be acceptable to customers and regulators alike?

- Have I considered whether there will be any consequences by making a change in passing rates for my facility?

- What risks are we potentially introducing into our operations if employees do not completely comprehend our workplace safety and food safety fundamentals?

- Will this imply to employees that training is now less important?

- What time commitment will be required to identify employees needing specific topic remediation, schedule employees for remediation, re-train, and take employees off the floor for a 2nd time?

- Will there be less emphasis on paying attention during training time?

- Will we experience less focus on important topics?

FINAL THOUGHTS

Sometimes the push to take less time or to do things faster clouds the purpose and benefit of achieving a baseline of key foundational knowledge. Using a 100% passing rate underscores the critical nature of setting a high bar for learning and development, fully engaging learners, and reducing operational risks.