Streamline Business Processes with New LEAN Manufacturing Courses

Intertek Alchemy is excited to launch a new Lean Manufacturing Library of eLearning courses to help managers and supervisors identify and eliminate inefficiencies and production waste in their organizations.

Companies across the world are struggling with labor shortages, shrinking profit margins, and increased costs as supply chain challenges continue. In this environment, any downtime, production delays, or product defects are amplified and can have a devastating impact on businesses.

Intertek Alchemy Lean Library content trains operations leaders across industries to define and map critical processes so their companies can run more efficiently and cost effectively. The training program provides easily digestible courses for large enterprises and smaller companies to help them immediately implement solutions that make a real impact.

Intertek Alchemy designed Lean Manufacturing Library courses to be industry agnostic, helping leaders from restaurant kitchens, to manufacturing facilities, to automotive plants, and much more. Each course is full of practical information and includes a resource guide so participants can put into practice what they have learned.

The Intertek Alchemy Lean Library includes the following courses:

- ABCs of Lean – This module introduces the ideas behind lean manufacturing, including identifying waste, understanding “just in time” production, and creating a safer, more productive work environment.

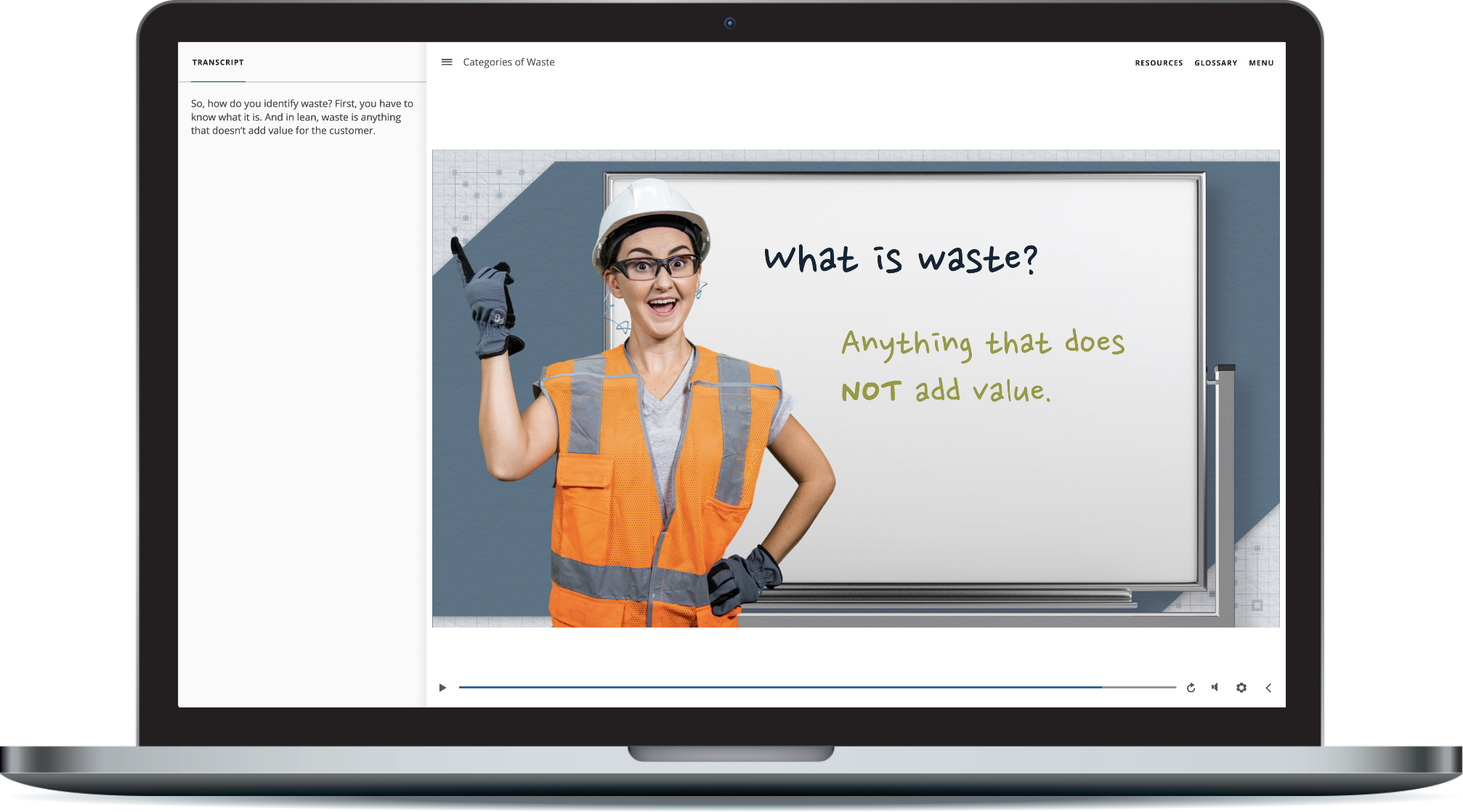

- Categories of Waste – Eliminating waste is one of the fundamental principles of lean manufacturing. This module explains the eight types of waste and suggests countermeasures to prevent or eliminate each type.

- Documenting Activities: Value Stream Mapping, Workflow Diagrams – This module provides tools to identify waste at manufacturing sites and workflows.

- Examining Data – Spreadsheets, Pareto Charts, Five Whys – In this module, participants will learn three approaches to examining data in order prioritize issues and determine root causes of problems.

- Identifying Solutions – Brainstorming, Fishbone Diagrams – This module introduces two tools that are commonly used to identify potential solutions: brainstorming and fishbone diagrams.

- Identifying Solutions – Kaizen, PDCA – Once organizations identify problems at their sites, they can use this module to discuss methods for developing action plans, evaluating solutions, and maintaining changes.

- Implementing Solutions – Kanban, Performance Management Boards – One of the best ways to identify and eliminate waste is to study workflow. This module introduces two lean manufacturing tools that can help organizations with Kanban boards and performance management boards.

- Implementing Solutions – Line Balancing, Takt Time, Pull Systems, Changeovers – One of the biggest challenges in lean manufacturing is making adjustments to the production line. This module will go over strategies for eliminating bottlenecks, creating smoother changeovers, and balancing the line for more efficient workflow.

- Implementing Solutions – Workplace Organization – Continually improving processes and reducing waste is the goal of lean manufacturing. Implementing 5S can help reach both goals.

- Verifying Solutions –Standardization, Audits – These tools help organizations document processes in a way that is easy to follow, even when new personnel come on board.

To request a preview of the courses of these courses, click here.