How an Effective Cross-Training Program Impacts the Bottom Line, and How to Make it Happen

In the ever-evolving realm of manufacturing, the ability to adapt is paramount to staying competitive. At the heart of this adaptability lies the strength of the workforce. In an era where specialization can sometimes lead to siloed expertise, on-the-job training and cross-training programs emerge as indispensable tools for fostering versatility and resilience within manufacturing teams.

This blog delves into the critical importance of on-the-job training (OJT) and the establishment of robust cross-training initiatives in manufacturing facilities. We’ll explore not only why these programs are vital but also how to develop and sustain them effectively, empowering organizations to thrive amidst evolving industry demands.

Why On-the-Job Training Matters

In short, OJT matters because it’s happening… a lot. New research, “Training Methods and their Impact on Workforce Performance in Manufacturing,” surveyed over 1,000 manufacturers. Among the findings, on-the-floor training happens even more than structured classroom training or eLearning. In fact, 73% of companies deliver training to frontline employees using on-the-job supervisor coaching and peer-to-peer instruction is present in 61% of manufacturing facilities. This showcases that worker-to-worker instruction is omnipresent, happening in nearly every facility. Since that’s the case, we better make sure it’s accurate!

Unfortunately, this isn’t always happening. From the same study, we find that 1 in 5 manufacturing companies report when one of their workers is teaching another worker, the instruction is incorrect and/or not following company policies. And only 14% of companies are strongly confident in the accuracy of worker-to-worker instruction. So, it should be no surprise the survey also highlighted the #1 reason employees don’t follow SOPs is they “prefer doing things ‘the old way’ / bad habits.”

In order to eliminate this knowledge gap, there has to be a structured cross-training program put into place that both engages and educates. Extra emphasis should be placed on the word “structured.” And we should add governed or monitored to the list of important characteristics. After all, how else would all those employees be learning “the old way” but from other workers in an unstructured, ungoverned setting.

With that context, let’s dive into a few ways you can develop and maintain a strong OJT program that delivers consistent, accurate instruction!

The Blueprint for a Successful On-the-Job Training Program

Begin by identifying the specific skills and knowledge gaps among your workforce that need to be addressed. Understand your key objectives for each job role and task whether that be to increase productivity, reduce errors, improve safety, or promote employee engagement. To achieve those goals, you must tailor your training content to the unique needs of your frontline workforce.

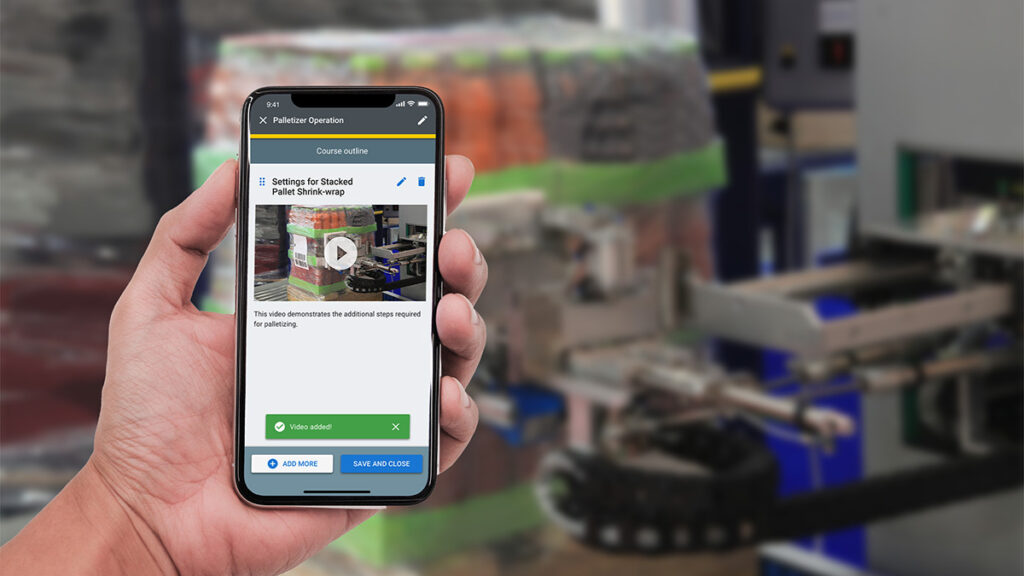

When cross-training on job-specific functions, the fastest path to proficiency that remains safe is realistic on-the-floor instruction, but without the trainee doing the work or using the equipment until they’ve demonstrated competence and thorough comprehension. The best way to do this is with a mobile training app that can deliver the job-specific training on the floor, at the equipment that will be used.

One such mobile on-the-job training app is Alchemy Playbook, which can ultimately replace paper SOP binders for good. Hundreds of manufacturers use Playbook to easily create job-specific training. A common method is to record video of the procedure being done correctly within the app, and then add step-by-step instructions, with intermittent knowledge checks to cement and document understanding.

This cuts down on the spread of bad habits two ways. First, it ensures OJT is consistent, since only approved admins can finalize course creation and manage updates, guaranteeing all floor training is accurate according to company policy. Second, when you have a new worker follow along with another worker — often called the buddy system — the more tenured worker will be using this app with the company-approved courses to deliver all instruction, and the learner is validating comprehension within the app.

Transforming OJT into a mature cross-training program is made simpler with this app technology as well. For example, a second component of Alchemy Playbook is the establishment and tracking of job qualifications. Companies can easily create a set of criteria that must be met before a worker is qualified for a particular position (such as a series of OJT courses, on-the-floor observations, classroom courses, etc.).

The app makes it easy for operational leaders to see the progress of workers toward qualifications. In addition to giving employees a clear path to progression — which leads to stronger employee engagement and retention — this gives leaders an instant view of specific jobs that need more qualified workers, and who to call upon if someone misses work.

One way to connect with your frontline workforce further is through feedback and evaluation. Establish a feedback loop to monitor trainee progress and identify areas for improvement. Regular evaluations can help fine-tune the on-the-job training program and ensure its effectiveness. Make sure you’re facilitating open communication between trainers and trainees to address any concerns or issues that arise.

Lastly, make sure you’re promoting a culture of learning. Foster a culture that values learning and professional growth at all levels of the organization. Recognize and reward employees who actively participate in training initiatives and demonstrate a commitment to self-improvement. Showcase how important collaboration is among team members and celebrate achievements (big and small) along the way.

By following these steps, you can develop a robust on-the-job/cross-training program that empowers frontline workers and manufacturers to thrive in their roles and contribute to the success of the organization.

The Positive Impacts of a Mature Cross-training Program

Cross-training opportunities expose workers to different aspects of the entire operation, not just their individual role. This not only broadens their skill set but also enhances team collaboration and flexibility. Showing your workers there are ways to broaden their skillset creates a sense of motivation. This not only improves employee retention, but your on-the-job training program can also stand out as a part of your recruitment process to attract motivated workers.

Assessing the impact of your on-the-job training program is a huge factor in all of this. You’re going to want to look at your productivity, quality metrics, employee satisfaction, and retention rates after implementing your OJT program and cross-training initiatives.

Earlier we learned the bad results when OJT is absent or goes unmonitored. But what happens when cross-training is strong, structured, mature, and utilized?

The research, “Training Methods and their Impact on Workforce Performance in Manufacturing,” compared manufacturing companies with strong cross-training programs in place to those without. The difference is astounding. Companies with strong cross-training programs experience:

- 68% improvement of employees consistently applying established protocols on the floor,

- 44% lift in workers teaching other workers correctly,

- 42% increase in employee motivation,

- 97% greater likelihood their training program has a positive impact on employee retention.

With results like that, the next time quota-focused leaders say there’s no time for training or employee development, share these stats to demonstrate why not making this effort is doing your bottom line a disservice.